Expansion joints are a critical component in the construction and maintenance of various infrastructure projects, including roads, bridges, buildings, and railways. These essential elements ensure the longevity and durability of structures by accommodating movements caused by thermal expansion, shrinkage, seismic activity, and other environmental factors.

Functions of Expansion Joints

- Accommodating Thermal Expansion and Contraction: The core function of expansion joints is to manage the physical changes that construction materials undergo due to temperature fluctuations. This dynamic is particularly pronounced in long structures like bridges and highways, where even minimal temperature variations can result in significant expansion or contraction across the structure’s length.

- Mitigating Seismic Impact: In regions susceptible to seismic activity, expansion joints are engineered to absorb and dissipate energy, thereby minimizing the risk of catastrophic structural failures. These specialized seismic joints are designed to accommodate lateral, vertical, and longitudinal movements, ensuring the structure remains intact and functional even under seismic duress.

- Addressing Material Shrinkage and Creep: Concrete, among other materials, undergoes shrinkage and creep over time, which can induce stresses within the structure. Expansion joints counteract these effects by allowing sections of the concrete to move independently, thereby reducing stress concentrations that could lead to cracking or other forms of structural compromise.

Advanced Applications and Considerations

- Bridges and Highways: These structures are particularly reliant on expansion joints due to their exposure to direct sunlight, varying weather conditions, and significant daily and seasonal temperature shifts. The design and placement of joints in these contexts are critical for maintaining surface continuity and user safety.

- Buildings and Architectural Structures: In buildings, particularly high-rises, expansion joints play a crucial role in accommodating not only thermal expansion but also building sway caused by wind or seismic activity. These joints must be strategically placed to account for both vertical and horizontal movements, often resulting in complex engineering solutions that balance structural needs with aesthetic considerations.

- Railways and Metro Systems: Rail tracks and metro systems require expansion joints to maintain alignment and prevent buckling due to thermal expansion. The precision in design and installation in these contexts is critical for ensuring the safety and efficiency of rail operations.

Spotlight on Connolly Expansion Joints

Connolly Expansion Joints are engineered for excellence in slab-on-ground applications, recognized for their reliability and straightforward installation process. These expansion joints are designed to maximize load transfer efficiency and accommodate joint expansion with robust construction materials.

Enhanced Design and Material Innovation

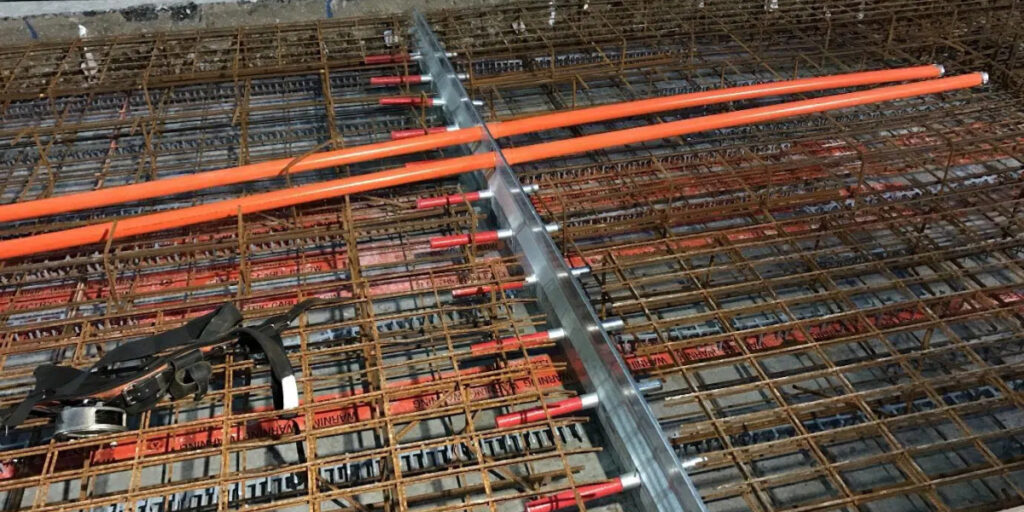

The Connolly Expansion Joint system incorporates roll-formed galvanized steel sections paired with 10mm cross-linked foam. This combination is meticulously chosen for its strength, flexibility, and resistance to environmental factors, ensuring long-term durability and performance in various construction settings.

Features and Technical Advantages

- Continuous Pour Solution: This feature streamlines the concrete pouring process, significantly reducing labor and time. It allows for a seamless construction workflow, which is crucial for meeting project timelines and ensuring structural integrity.

- Precision in Load Transfer: The system’s design focuses on efficient load distribution through dowels. This precision ensures that the structural load is managed effectively, reducing stress on the concrete slab and enhancing the overall durability of the construction.

- Durable and Resistant Construction: Connolly Expansion Joints are built to last. The use of galvanized steel ensures a high level of protection against corrosion, while the cross-linked foam provides resilience against environmental stresses, contributing to the longevity of the infrastructure.

- Innovative Installation Features: The patented peg and wedge system facilitates easy and accurate positioning of the expansion joint, allowing for quick adjustments on-site. This not only simplifies the installation process but also ensures precise alignment and height adjustment, critical for the joint’s performance.

- Comprehensive System Components: Each Connolly Expansion Joint system comes equipped with pre-formed holes designed to work seamlessly with Connolly Universal Dowel Sleeves (UDS). This integration accommodates round dowels up to 30mm in diameter and square dowels up to 24mm, ensuring versatile application across various project requirements.

- Optimized for Environmental Adaptability: The system is designed to allow up to 10mm expansion, providing ample capacity for thermal expansion and contraction. This feature, combined with additional stiffening ribs and a galvanized coating for corrosion protection, makes the Connolly Expansion Joint a reliable choice for maintaining structural integrity under variable conditions.

The Connolly Expansion Joint system is available in 3m lengths for slab thicknesses from 100mm to 200mm, offering a range of solutions to meet the demands of slab-on-ground construction projects. With its focus on durability, efficiency, and ease of installation, Connolly Expansion Joints are crafted to provide a robust solution for managing concrete expansion and ensuring the longevity of construction projects.

Custom Expansion Joints from Danterr

Danterr recognizes the unique demands of various construction projects, emphasizing the importance of a perfect fit and superior performance in expansion joints. Our custom solutions are designed to meet the specific needs of your project, ensuring long-term reliability and efficiency.

The Perfect Fit for Every Project

Our custom expansion joints are engineered to accommodate nonstandard distances between structural components, such as pipe flanges, ensuring a seamless integration regardless of the project’s complexity. With a focus on minimizing stress and avoiding overexertion on the structure, these joints are tailored to provide the best fit, enhancing the structural integrity and longevity of your project. The availability of various finishes allows us to design a solution that not only meets your technical requirements but also complements the aesthetic considerations of your project.

Engineered for Superior Performance

Danterr’s custom expansion joints excel in functionality, offering unmatched control over pressure and vibration while providing the necessary flexibility at critical junctures. By designing each joint to suit its specific location and function within the structure, we ensure that our solutions enhance the overall performance of the infrastructure, making them ideal for demanding environments where precision is key.

Simplifying Installation, Enhancing Efficiency

Recognizing the challenges of onsite installation, especially for joints exceeding 200mm, our custom expansion joints are designed for ease of installation, significantly reducing labor time and potential for error. This streamlined installation process not only improves the efficiency of your project but also contributes to the overall timeline and budget management.

Highlighted Project: Sydney Light Rail

A prime example of the effectiveness of our custom solutions is their application in the Sydney Light Rail Project. Danterr supplied custom expansion joints that simplified the installation process, ensuring smooth operation and structural integrity throughout the rail system. The use of transverse key joints, designed for continuous concrete pours and capable of accommodating expansion, demonstrates the practical benefits of our custom solutions in large-scale infrastructure projects.

Connolly Expansion Joints and Danterr’s custom solutions offer critical support for the durability and integrity of various construction projects, ensuring tailored, high-performance outcomes. Danterr, with its commitment to innovation and quality, stands ready to meet the specific needs of your projects, whether through standard solutions or customized expansion joints. For those requiring detailed consultation or looking to place bulk orders, Danterr’s expert team is just a call or email away at sales@danterr.com or 1800 262 383. Partner with Danterr for your next project to ensure excellence in construction with reliable expansion joint solutions.

FAQs

Expansion joints are utilized to absorb vibrations, allow for movements due to thermal expansion and contraction of construction materials, and accommodate for ground settlement or seismic activity, ensuring the structural integrity of buildings and infrastructures.

They are required in concrete slabs and pavements, between sections of buildings, bridges, sidewalks, railway tracks, and in other structures that are prone to movement due to thermal changes, material shrinkage, or seismic activities.

Yes, expansion joints are essential in concrete to prevent cracking caused by thermal expansion, contraction, and other movements. They are especially important in large concrete slabs and where there are consecutive concrete pours.

Expansion joints are placed at specific intervals within a structure, such as where two sections of a building or bridge meet, and around perimeters of structures, to accommodate movement and prevent structural damage.

Yes, they are crucial for maintaining the longevity and integrity of structures by preventing cracks and damages due to the natural movement of construction materials.

Without expansion joints, concrete is likely to crack and suffer structural damage due to the inability to move freely with thermal expansion, contraction, and other movements.

The recommended spacing between expansion joints in concrete constructions can vary, but for buildings longer than 45m, an expansion joint is generally provided, with recommended center-to-center spacing of 30m.

The thickness of the material used in expansion joints, such as the filler material, is designed to accommodate movement and can vary based on specific project requirements.

While specific minimum thickness can vary depending on the application, expansion joints must be designed to accommodate the expected range of movement within the structure effectively.

For a slab that is 100mm thick, expansion joints should be cut at least 25mm deep, which is generally a quarter of the thickness of the slab, to effectively allow for expansion and contraction.

A construction joint is where two concrete placements meet and is designed to allow for displacement between both sides of the slab while transferring loads. An expansion joint, however, is specifically designed to absorb expansions and contractions of the material, allowing for movement without transferring significant stress to the structure.

Stay Updated with Danterr!

Subscribe to Our Newsletter for the Latest in Construction Solutions