Sustainable and green building is the future of construction. It must be – there is not one exception. Not only does it help to protect our environment, building green can reduce the cost of building construction operation over time and in many cases extend the life span of a building. Perhaps the most important aspect of green building construction is getting the old heads in the business to change their ways. Getting a baby boomer contractor to use new, sustainable and potentially more expensive but longer lasting building materials isn’t a job for the weak.

Back in 1987, when the wall was still up, and Regan was only 85% gone, the UN-commissioned The Brundtland Report ‘Our Common Future’ which described sustainable development as ‘development that meets the needs of the present without compromising the ability of future generations to meet their own needs’.

More than three decades later, this definition continues to be relevant – especially in the context of population growth and climate change.

So, what defines ecological construction? The simplest description would be constructions that have minimal impact on the environment through the application of appropriate design concepts, materials, and technologies. But these buildings need to also ensure ongoing benefits for future occupants in the form of energy efficiency, and comfort throughout the lifecycle of the building.

Danterr identified this trend early and invested heavily in our unique product called Equinox which are walls insulated with an ecological form of foam that keeps rooms the same temperature year round. This reduces the need for heating and cooling. This theory not only works well in high rise apartment buildings but also in government buildings such as schools, houses of parliament, even jails.

Identifying sustainable building materials may seem easy, but when you really think about it, how easy is it? For years, our buildings have been primarily made up of concrete, steel, glass and brick – concrete is actually the 2nd most consumed product on earth behind water!

As material shortages become the norm, increasing costs of raw material, and concerns over the recyclability of building materials grow, the interest in alternative materials does as well. Danterr is one of several companies that saw a major increase in the price in traditional forms of steel coming, so Danterr branched out into the sphere of fibreglass reinforcement, a product that is ten times better for the environment than steel, and will increase the life span of a building by up to 100 years if enough of it is used.

What is interesting about many of these alternatives is that they are not brand-new ideas. Some are like our Equinox walls, but others are not. There has just been a slow and steady movement towards a green future but let’s hope for the generations to come the momentum continues to increase.

An example of recycling that not everyone might have known about is recycled steel. Steel is actually one of the most recycled building materials in the world. In 2021, 89% of all steel produced is destined to be recycled. Today recycling steel to create new steel products is a staple in the industry.

The industry goal should be to make recycling a standard just like it is with steel. However, a big impact on the industry can come from the choices that contractors make when choosing and suggesting building materials.

Danterr has just added to its range QPODS™ which are a like-for-like replacement for unbreak-downable polystyrene Waffle Pods when it comes to concrete flooring. These QPODS™ are lighter, easier to move and come from 100% recycled plastic.

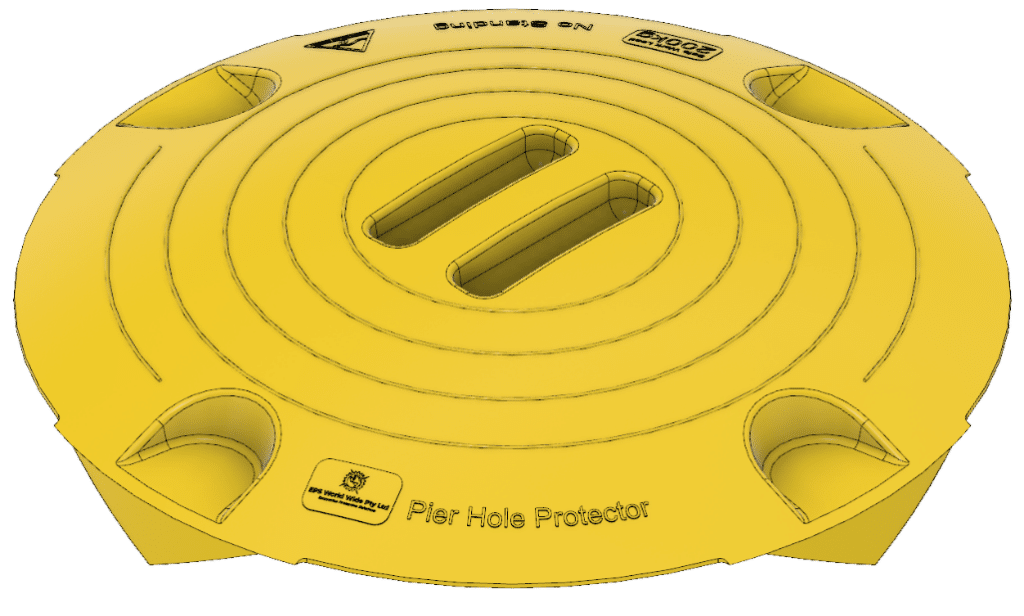

Danterr too are about to add to our range a Pier Hole Protector – a gadget that looks like this…

That, get this… gives buyers the option of a Pier Protector manufactured from 100% recycled material or virgin material which can then be recycled in the future!

What Makes Green Building Construction Materials Different?

There are five factors separating green building construction materials from others.

1.The product does not have to travel far to get to your site, and there is a lot of it.

Using locally sourced materials eliminates international shipping and with it, the environmental impact that goes into sourcing the material. If we shop at the businesses in the vicinity of a project, it majorly reduces the carbon footprint of material sourcing.

The same can be said for equipment. If a project is out in the middle of Australia but still needs heavy duty equipment from your business, consider renting local equipment instead of shipping large machines across long distances. Going local is a great first step in attempting to be greener.

2. Recyclable Materials

As discussed above, there are two parts to choosing recyclable building materials when a company is building a major infrastructure project that must be safe to use and have a cost-effective life span.

Step one is to watch a five-minute YouTube clip about materials that can be recycled. As the hundreds of videos indicate, many kinds of materials can be recycled. Concrete, steel, plastic, wood and even bricks can all be recycled – all are covered in this VIDEO HERE. There are a few materials which cannot be recycled, such as broken glass and some plastics. But if we reduce these materials to start with and find a substitute, our kid’s kid’s kid’s will thank us! Obviously focusing on using materials which can be recycled is step one.

Recycling concrete in real time

Step two is to ACTUALLY RECYCLE these materials. Construction materials in large quantities such as concrete or steel cannot go to the local city recycling facility. So, study needs to be done well ahead of time where these materials can be recycled – sometimes it might be offshore then a calculator is needed to derive the benefits. Either way a plan must be implemented onsite about just how they will be separated, stored, and shipped to the recycling facility. Using recyclable materials is only good if the materials are actually recycled.

3. Buy and use Recycled Materials

Then the bosses, the engineers, the site supervisors and maybe even the investors must be convinced to choose materials which have been made from recycled products. Plastic that has been recycled into a variety of construction items is a great place to start. Then you can get into the more heavy-duty products like asphalt as this video brilliantly depicts…

Following a lot of internet time, there are seemingly more and more sites popping up advertising green construction everyday. When glued to the screen one can learn that recycled building materials come in a variety of shapes and sizes and come from some surprising sources. There are so many different kinds of recycled materials out there; Cinder blocks made from plastic bags, tiles created from wine corks, and even walls grown from mushrooms! There is not much we cannot do as humans if we put our minds to it to ensure we have a sustainable future.

Recycling materials is a great way to add sustainability to a project. Both sourcing recycled materials for building and recycling extra materials are two ways to incorporate recycling into your sustainable construction plan.

4. Longevity

The stronger, more durable building material you choose, the longer it will last. The longer it lasts, the less material needed to replace or repair it in the future. Fibreglass reo is a perfect example of this for marine constructions. Fibreglass reo when replacing steel takes a great deal of engineering, time, and effort; so why it is no doubt better for the environment, it is by no means easy. Not easy like a simple hessian roll! To help concrete cure you can buy a curing blanket that is made from materials that won’t breakdown in a thousand years and are laced with chemicals; or you could use a simple Hessian Roll which are a cheaper and much greener alternative to traditional curing blankets.

5. Green Manufacturing

One of the last ways to source sustainable building materials is to look at where and how the material is created. Choosing suppliers that also practise environmentally friendly processes means that your materials have an environmentally friendly life cycle. Many companies use their environmental practices to differentiate from their competition and advertise their green initiatives. We do!

Green manufacturing can include green manufacturing buildings, using renewable energy sources, choosing toxic-free materials, and disposing of the manufacturing by-products in an environmentally friendly way. On top of this, the entire process of reducing waste, recycling materials, and keeping a green project can save money while making the work environment healthier.