Where waterproofing concrete is concerned, the joints are where the millennia-long battle between water and concrete peaks; these joints are most likely the weakest points of the structure. Concrete joints are highly susceptible to water infiltration, which, without proper protection will lead to the deterioration of the concrete and indeed all immediately present steel reinforcement. As a result, concrete joints require a considerable amount of protection.

That brings us to Hydrotite…

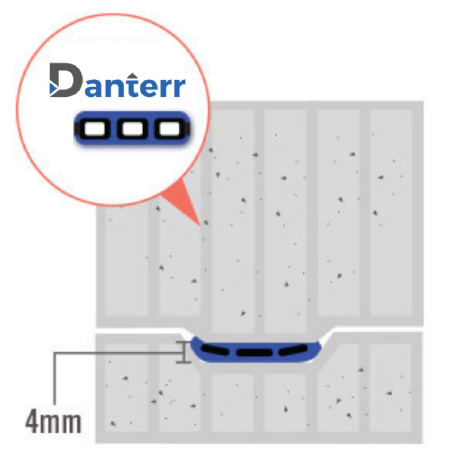

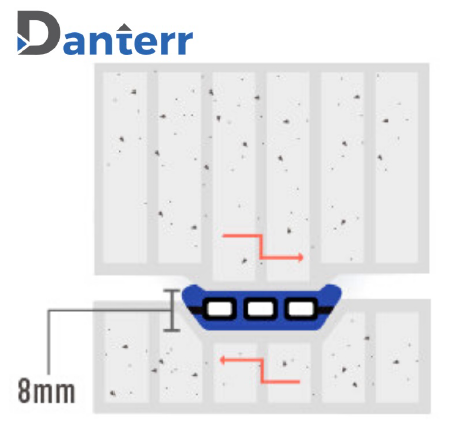

Hydrotite has been specifically designed and developed from hydrophilic material to provide robust permanency, defiance against long-term stress relaxation, as well as protection from microbial attacks/deterioration in all concrete joints. The co-extruded profiles of Hydrotite control the direction of expansion across joints, rather than along the path of least resistance. This ensures BOTH, that higher contact surface pressures are achieved; and improved water sealing results are sustained.

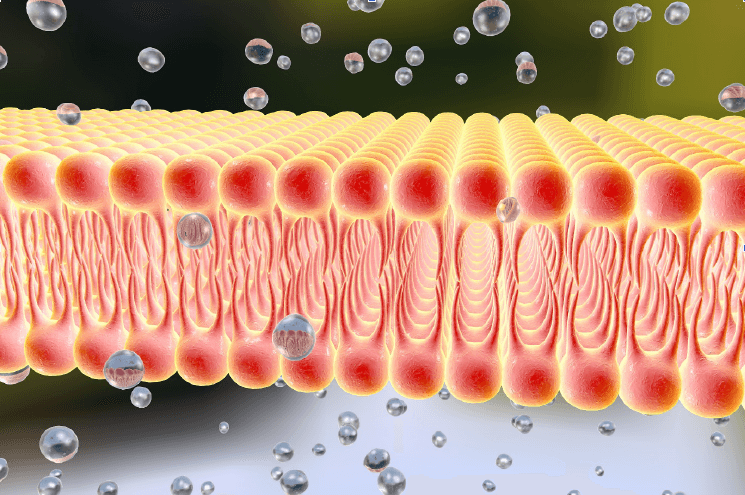

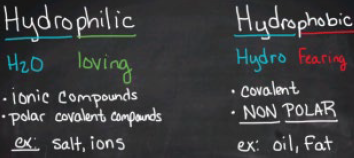

A Hydrophilic Contact Surface

When water hits a surface, sometimes it spreads evenly and sometimes it beads into tiny droplets. While people have noticed these differences since the beginning of time, a better understanding of the why and new ways of controlling them, is what we must thank for the development of hydrophilic surface products, and in particular HYDROTITE!

In a very simplified nutshell, it is as simple as this… materials with a special affinity for water — those water spreads across evenly thus maximizing contact are known as hydrophilic. Surfaces that naturally repel water, causing droplets to form, are known as hydrophobic. Both classes of materials can have a significant impact on the performance of everything from nuclear power plants to computers, to airplane wings and for the sake of this blog – to joints in concrete

High Expansion Capacity

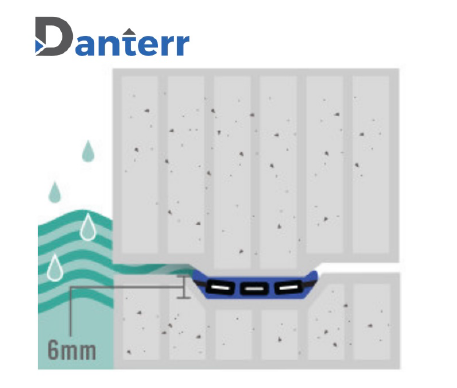

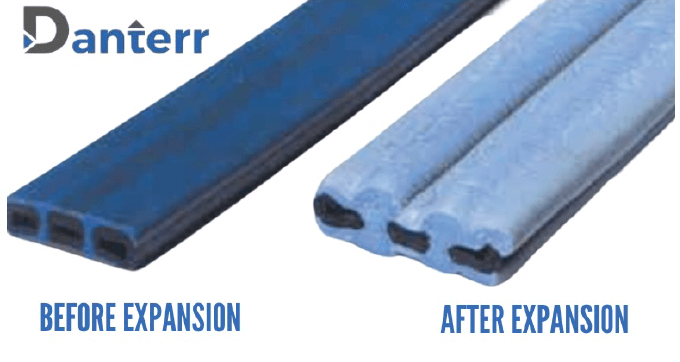

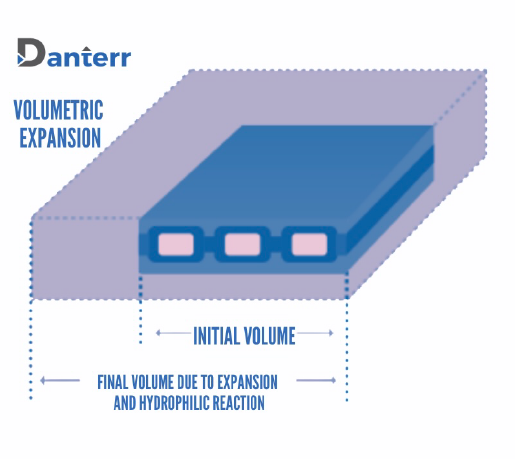

The high expansion capacity of hydrophilic surface material Hydrotite, provides an initial compression seal with reserve expansion capacity to accommodate future joint movement. The hydrophilic surface polymers Hydrotite incorporates are the best commercially available product. They swell up to eight times their original size upon contact with water.

Initial compressed seal

The way Hydrotite is engineered with rubber elasticity and a hollow core allows an initial compressed seal between adjacent surfaces during construction.

Hydrophilic reaction

When Hydrotite is met with water, a hydrophilic reaction occurs meaning water is attracted and spread evenly, which produces a secondary expansion following contact with water thereby ensuring a water-tight seal is maintained.

Residual expansion

Should the future produce any related structural movement, Hydrotite will have provided residual expansion to ensure a high contact surface pressure and watertight seal is maintained.

Expansion delay coating

One of the best features of Hydrotite is its delay coating. The coating on Hydrotite delays premature expansion should the product be met with any rain or groundwater before installation. The delay expansion coating also allows freshly poured concrete to cure before expansion begins.

Hydrotite verse PVC Waterstop

PVC water stops are not as tolerant of typical concrete construction practices as Hydrotite and cannot accommodate for concrete shrinkage without leaking. Hydrotite, by comparison, as discussed above, is formed by ‘active’ hydrophilic material, and has the capacity to expand by absorbing water into its hydrophilic matrix. This expansion capability compensates for movement and shrinkage, which generally occur in concrete structures.

Hydrotite verse Bentonite Waterstops

Bentonite-based water stops can expand of only 1-to-2 times their original volume. With Hydrotite, that number is up to eight times its original volume thus ensuring a tighter seal. Secondly, without constant monitoring, bentonite materials can continue to swell in an uncontrolled fashion and lose their physical properties after prolonged exposure to saturated conditions. Then there is the hydrostatic element; bentonite-based water stops frequently fail when subjected to hydrostatic pressure – the biggest factor in dam/water tank construction. Also, most bentonite water stops do not have a delay coating either, which results in premature swelling in un-cured concrete, or if the product gets wet before installation.

Hydrotite verse other Hydrophilic waterstops

Other hydrophilic materials are manufactured from inferior rubber to Hydrotite, which provides inferior long-term durability. Rubber products of this nature are prone to stress relaxation and microbial attack over time. Inferior (natural) rubber materials also provide reduce rates of expansion, which may not maintain long-term sealing integrity after joint movement.

Hydrotite is manufactured from synthetic rubber to provide excellent durability over time and exhibits improved resistance against long-term stress relaxation and microbial deterioration/attacks.

Moving Forward

Hydrotite is one of the most sort after commodities in Australian construction. At Danterr we take great pride in being one of Australia’s leading distributors of this magnificent product.

2020 may have been the year of Covid-19, but the year of the Australian freshwater crisis too may have occurred in the shadows. Yes, concrete structures of all kinds have joints that need waterproofing, but we are too seeing more federal funding going towards dam and catchment projects. These projects will ensure Australia’s clean water future, and all will need a whole lot of Hydrotite!