If you don’t fancy reading this MAGNIFICENT blog, then please click this link to get straight to Danterr’s range of Fibreglass Reo.

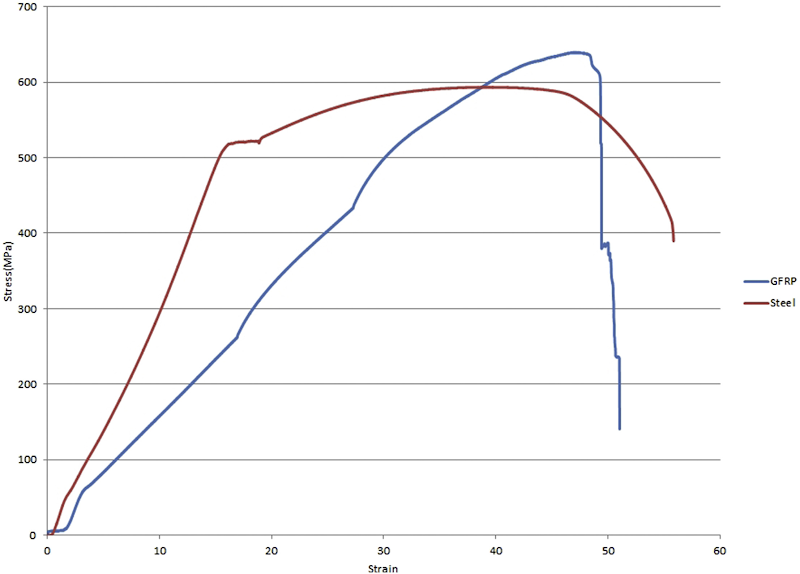

Make no mistake… upon initial outlay, Fibreglass Concrete Reinforcement – Glass Fibre Reinforced Polymer (GFRP from now on in this blog), is more expensive than traditional steel reinforcement. However, of course, steel reo is completely susceptible to corrosion or oxidation especially when exposed to saltwater and even salty sea air – GFRP will never corrode. As steel corrodes it swells thus increasing the tensile load on the concrete, which leads to cracks and spalling thus creating faster deterioration of the steel and concrete. This causes costly repair and maintenance and, if allowed to progress far enough, it can compromise the structure’s integrity. Therefore, the clear first and most likely most important benefit of GFRP is its effectiveness in saving costs by removing the need for any reinforcement related repairs for around 200 years.

At between ¼ and 1/7th the weight of steel reo, Glass Fibre Reinforced Polymer also requires far less labour thus decreasing installation costs. Due to its light weight, both human injuries and damage to the reo are minimised while loading or unloading material. The same goes when installing GFRP.

Market increase

The global Glass Fibre Reinforced Polymer market currently stands at over half a billion UDS annually. Over the last five years, the market has continued grown by around 8% annually. Rapid infrastructure development along with increase in construction spending are the key trending factors driving GFRP market size. In Australia, with several light rail projects having recently been completed, and with more slated for commencement, GFRP has increased in popularity due to it not conducting electricity.

Increasing corrosion issues in conventional reinforcement techniques has enhanced the product penetration in the infrastructure repairing industry. Over 25% of the overall construction failures are due to corrosion. Inefficiency pertaining to steel reinforcement causing concrete failures will positively influence the upgraded non-corrosive construction material adoption moving forward.

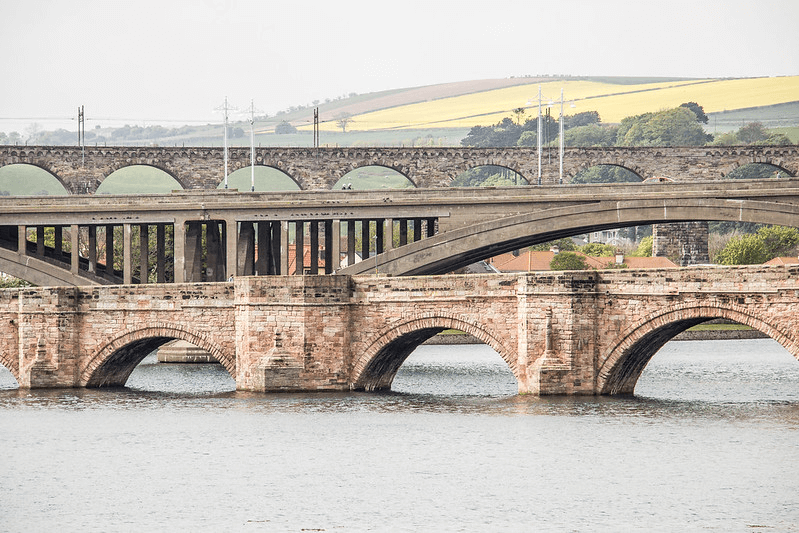

Increasing government spending on highways, bridges and buildings construction and renovation of deficient structures will continue to drive the industry growth. As per the U.S. Department of Transportation (DoT), the total number of structurally deficient bridges in the U.S. was 58,791 in 2019. In Australia, 70% of our bridges are over 50 years old. Advanced GFRP rebar structure along with high strength and polymer resin matrix transferring load between fibres, are among the key properties influencing the product penetration.

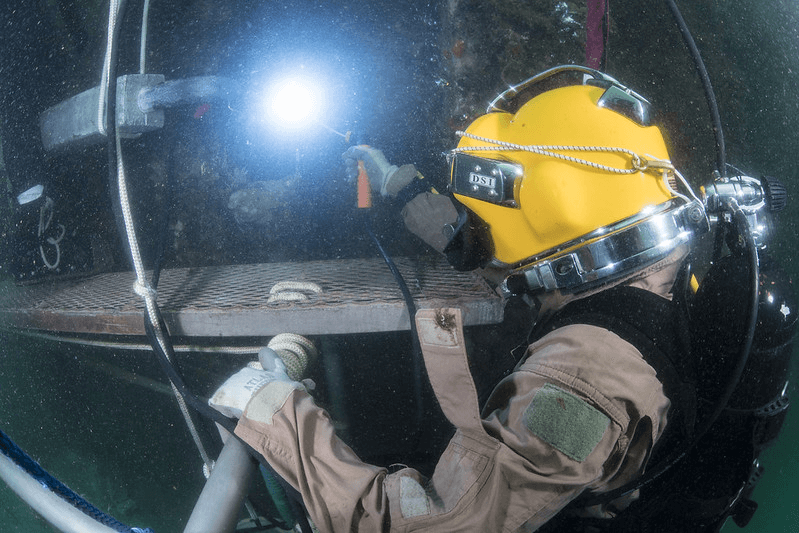

There are many future water treatment plants, marine structures, and MRI rooms application that will continue to propel the business growth in Australia. Prevention from concrete cracks on the marine pillars caused due to alkali and chlorine content sea water occurrence will enhance product demand from marine structure. Highly durable GFRP rebar with leakage control and crack control properties acts as ideal reinforcement for underwater applications.

Increasing government budgets on construction and repairing in the emerging economies has positively influenced GFRP rebar market share. For instance, China spent over 2.5 trillion AUD in 2019 on construction, while Japan spending registered over AUD 1 trillion in the same year. Rapid urbanization and industrialization leading to upgraded infrastructure and manufacturing facilities will support the product demand. High initial costs due to the expensive processing and raw material prices may impact GFRP rebar manufacturers profitability. Low adoption among the construction professionals and preference for cost efficient project will restrain the industry growth.

How to prevent corrosion?

Civil engineers around the world have created strict quality assurance standards to make sure the materials being used are of good quality. The mixture of materials is another way to keep them strong and retain their strength for a maximum period of time.

It is necessary to protect the concrete from damage by freezing and thawing cycles. Air also reduces exudation and is increased permeability due to exudation water channels. Peeling the concrete surface can accelerate the corrosion damage of embedded reinforcement bars.

Thus… a great solution to completely remove the chance of corrosion in building structures is the use of Glass Fibre Reinforced Polymer. This is an alternate material used for steel in the construction industry. The qualities of GFRP range from being corrosion free, being lightweight, having a long product life and being stronger than steel itself.

Sustainability

We are nowhere near the pinnacle of human evolution; however the way we construct and build structures proves that our existence has gained a new level of livelihood and we are still moving forward. This modernization of our development requires innovation as well. Innovation that will assure the safety, sustainability and the survival of our future generations. One particular feature of this evolution is the construction materials used in the infrastructure of the cities we live in. In this authors’ humble opinion, perhaps, the most influential material in construction today is Glass Fibre Reinforced Polymer (GFRP).

Most developed countries around the world are now relying on sustainable construction methods to save resources and provide buildings with a long service life. The use of traditional materials is decreasing and the use of new materials that can be recycled, reused and reduced consumption are being increasingly introduced. The use of GFRP instead of traditional steel is being used evidently. Especially in large structures, bridges, and buildings which are intended to last for a very long time.

Another Benefit

Being a polymer, GFRP is able to withstand the extreme weather conditions and continuous rain and water submerged conditions. As of 2019 testing regarding GFRP based structures, there has been no loss of strength, whereas steel and similar materials lose their strength-based attributes after a few decades.

GFRP Is Economic

Part of the cost of construction materials consists of transportation, weight, and storage. Being lightweight and having fewer chances of corrosion, the storage and transportation cost of GFRP is much less than steel.

Build it Once!

Some of the most useful aspects of GFRP are that its life expectancy and strength are greater than steel in all dimensions. Being a quarter of the weight of steel, the use of this material has been providing the construction industry the needed competitive edge in the market.

GFRP Is an Insulator

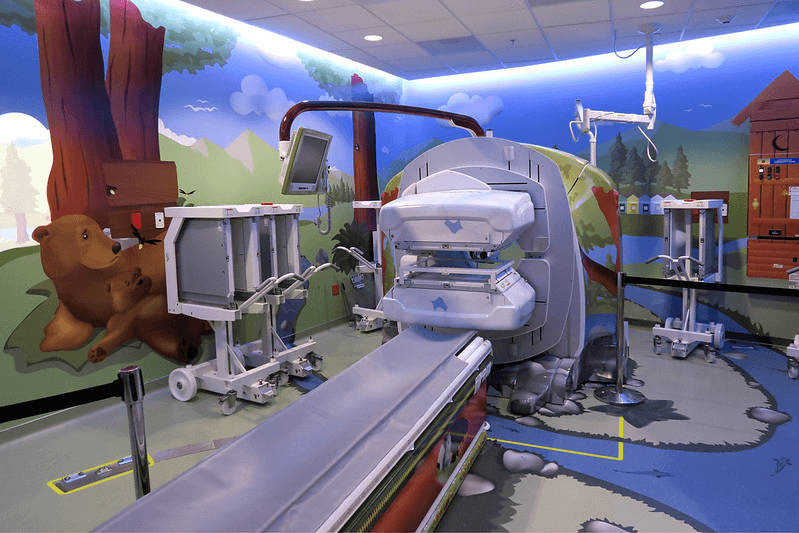

Steel of course, is a conductor of heat and electricity; this can sometimes be a problem, depending on its application. A good example would be hospital rooms with x-ray equipment. These rooms usually require GFRP reinforcement, as steel would cause issues.

Similarly, in extreme weather, heat and cold are conducted by steel. GFRP in this sense again becomes a useful alternative as it cannot conduct electricity or heat and cold. This provides extra assurance as to why fiberglass rebar is an excellent alternative to steel rebar.

GFRP For the Future

The construction materials for the future need to be more cost-effective and should have qualities that easily surpass traditional raw materials used in construction. The economic activity that is generated by construction is actually a collaboration of various other industries, therefore, it is important that innovation and modernization are practiced in all industries.

The global warming issue is getting worse. Weather conditions are becoming more extreme, natural calamities are becoming more ferocious every year. The cost of rehabilitation after natural disasters is worth trillions of dollars globally.

Next…

In both new and rehabilitation construction projects, design professionals need to explore the advantages of building environmentally friendly infrastructure with highly durable and innovative composite materials. GFRP is an example of how advanced composites can completely transform the public infrastructure and help structural engineers design more durable and cost-effective structures.

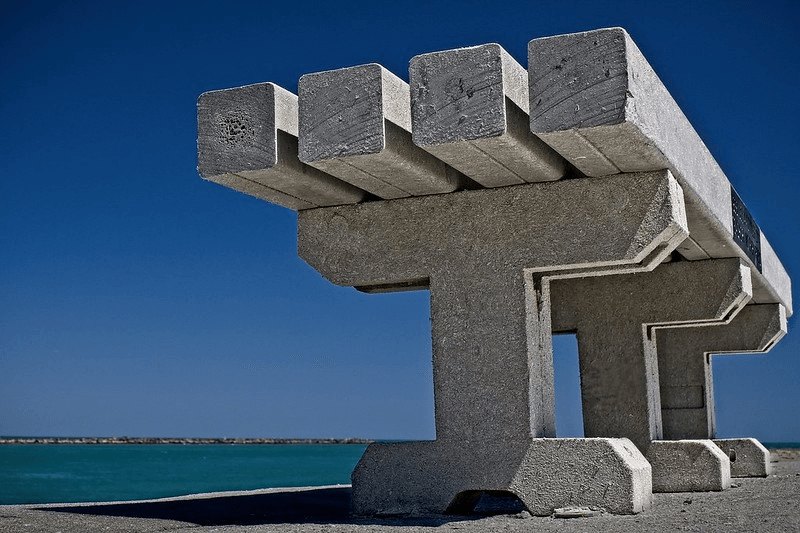

Marine

Concrete jetties, wharves, bridges, and seawalls are examples of marine structures subjected to environmental elements such as chlorides and weathering. GFRP reinforcement should be used for enhanced durability and longer service life. Design codes have been developed to make GFRP materials more suitable for use in waterside and other critical concrete structures. These composite materials also provide dependable reinforcement solutions to marine concrete rehabilitation projects. Marine structures play a pivotal role in marine resource exploitation and economic development.