Is it time to scrap Polystyrene as a void former in Australia?

Recently there has been a shift in the Australian market for sustainable concreting products. One product has received scathing reviews but what is so bad about it? And, what is the alternative?

First developed in the 1980s the Waffle Pod has always been popular as a cheap, quick and lightweight void former in concrete slabs for housing and commercial buildings. Often chosen due to their ease of use, Waffle Pods tout a reduction in the amount of concrete used for slabs but recently they have come under fire for their environmental impacts.

MENACE: John Nobbs with one of hundreds of waffle pods blown onto his father’s property from building sites in July. Picture: Robert Peet for Illawarra Mercury.

So, what are the Environmental Impacts?

Like other plastics EPS, Styrofoam or Polystyrene is non-biodegradable. But if these waffle pods are in concrete and the first cement structure Göbekli Tepe has been around for 12,000 years why does their ability to biodegrade even matter? Well, it is not their non-biodegradable nature that is the key environmental impact rather their innate ability to break, crumble and blow away in the wind.

Problem: A collection of photos showing polystyrene waffle pods that have blown off building sites at Wongawilli and West Dapto, causing an environmental issue. (Picture credit Illawarra Mercury)

The exact consequence of this nature has been observed in several towns over Australia after building sites have failed to secure their Waffle Pods for change of weather. The Council of Wollongong has even lobbied the NSW Government for stricter regulations or BANS on Waffle Pods and their handling. This course of action followed after EPS pods were blown from site on several occasions, causing pollution and styrene beads to find their way into all matter of environments including, water drains, lakes, dams and animal drinking spaces -both wild and farming.

So, what can be done to fix these environmental impacts?

In response to these calls for action the Expanded Polystyrene Australia released a voluntary code of practice for management of the pods. Further to this the National Waste Policy case study found that “where the Pod Scrap Bag Program has been implemented, the collection and recycling rate of EPS pod offcuts is extremely effective—around 90 per cent”. But in order for this program or code to be effective, sites must participate, manage and become responsible for the estimated 600 tonnes of offcuts from building sites in Australia.

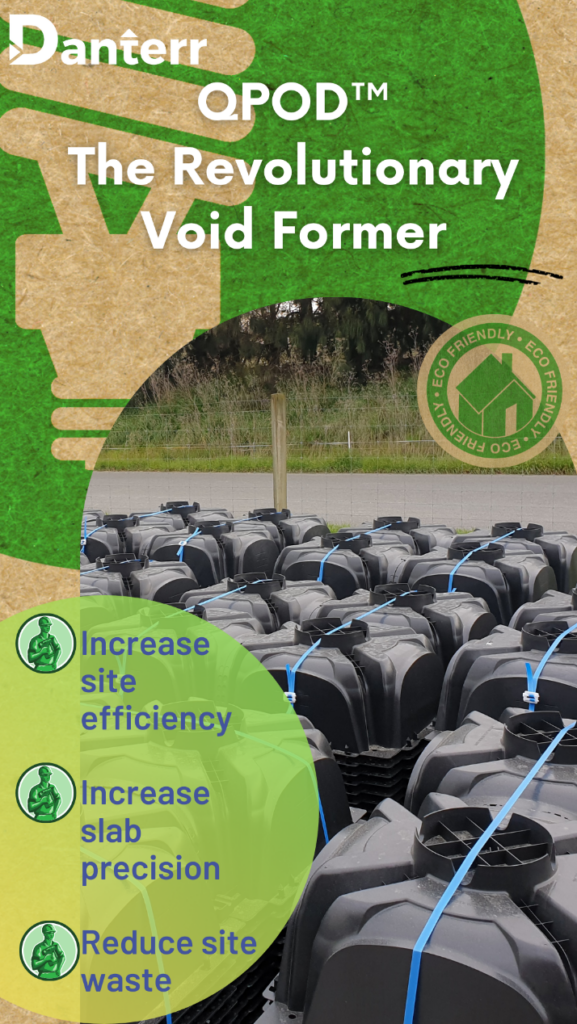

What else can be done? Well, you could choose a different product as a void former. You could reach for an alternative, something like QPOD™ – Our most recent product collab.

Courtesy of QPOD New Zealand

What is QPOD™?

QPOD™ is a 100% recyclable Flooring System that replaces polystyrene to not only protect the environment but reuse plastics that otherwise would have ended up in landfill. QPOD™ is manufactured in New Zealand from 100% recycled and reprocessed plastics -some of which have been old car bumpers, hotel toiletries and battery covers.

And there are many more benefits to QPOD™ systems that waffle pods do not deliver on such as their ability to be; stacked, stored and transported in smaller warehouses and Ute’s or pickup trucks instead of large freighters due to their hollow design. Infact, 50m2 of product can fit on one pallet.

Courtesy of QPOD New Zealand

Further, the QPOD™ raft slab is suitable as a sturdy base for under floor heating and all slabs have inbuilt patented 40mm barchairs that guarantee precision throughout the slab height.

Why QPOD™ over Polystyrene?

Well, there are less offcuts with QPOD™ and the product is secured by simply stacking the pods. Each QPOD™ weighs 1.2kg for ease of handling and the unique interlocking system keeps them in place during weather changes and the concrete pour.

Besides the above factors there is the imminent arrival of legislation or restriction regarding waffle pods on building sites. Coupled with this is the growing concern for the environment and the waterways that preserve and protect not only our wildlife but our play spaces, our parks and our neighborhoods. Just like children with bean bags our wildlife can choke from floating broken EPS pods too.

So perhaps waffle pods may remain the cheapest and most accessible material but alternatives are soon showing that anything is possible and here at Danterr we will always keep up with the future and its green capabilities.

If you want to step up your slab work and look after the world around you enquire about our QPOD™ today.