Editor’s Note: This post, originally published on November 22, 2019, has been thoroughly revised and updated to ensure accuracy and comprehensiveness.

How Do You Build a Modern Airport in a Challenging Landscape?

Building an airport is no small feat, particularly if it is going to be in a country as vast as Australia. From subways of big cities to remote outback regions, each place comes with different difficulties that need creative approaches. As commercial air travel continues to grow, the demand for new and improved airports is higher. However, how can one build these complex structures, especially in areas with limited space or difficult terrain?

Embracing Challenges with Danterr’s Innovative Solutions

At Danterr, we understand the intricacies of building airports in Australia and provide the products and expertise needed to overcome these challenges. Our comprehensive and superior concrete accessories and jointing systems contribute to developing strong and economically functional airport structures. This blog looks at how our solutions help to build new world-class airports in Australia, which are safe, durable, and sustainable.

Navigating Space Constraints

Space constraints are a global issue, and with commercial air travel being a relatively recent development, we can expect even more innovative airport designs. Danterr sources and distributes high-quality concrete accessories ideal for airport and runway construction. Our products have been integral in building new runways and airports in Australia, addressing the increasing need for air travel infrastructure. Additionally, we support Australia’s defence expansion, contributing to runway and base constructions with our comprehensive product range.

Your Next Project, Simplified with Danterr!

Enter your email to explore our top-quality construction solutions. We’re here to support your project’s needs with innovative, sustainable products.

Catalogue Form

Danterr’s Product Offerings for Building Airports in Australia

- Dowels are very essential in ensuring load transfer over concrete joints. They are useful in avoiding differential settlement alongside cracking in slabs since they provide space for horizontal movement. Dowels are very useful in large structures such as airport runways to enhance the life span of such structures.

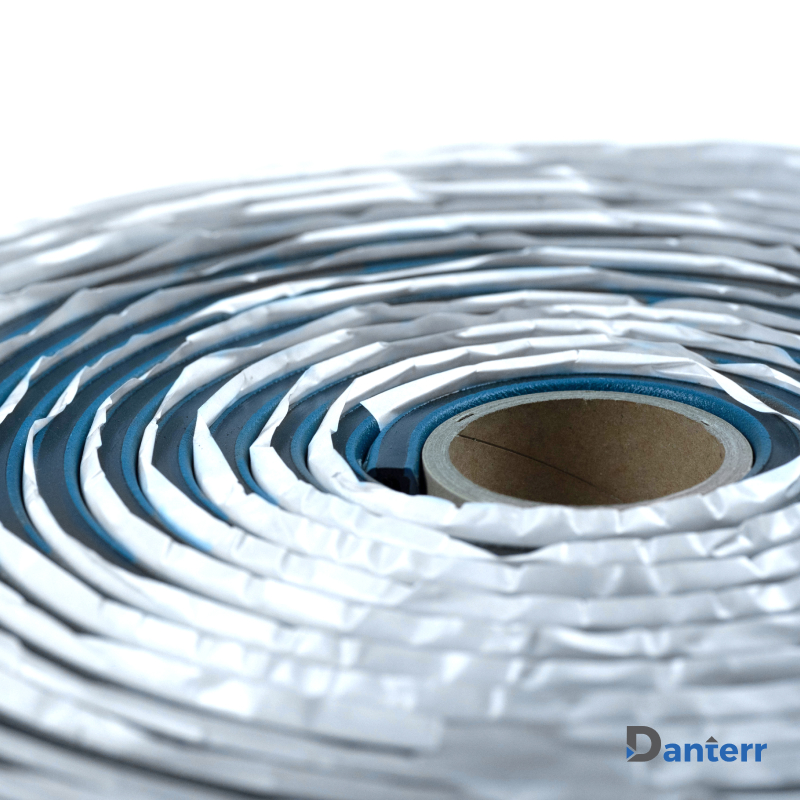

- FutureFlex™ Expansion Foam is intended for installation in concrete jointing systems as a filler for expansion and contraction forces. It is flexible and withstands the temperature changes and severities characteristic of the airport, to see that the joints are still functional.

- Hydrotite is a hydrophilic waterstop that prevents water leaks in structures made of concrete. It expands when in contact with water and can seal all the joints and cracks. This is important especially in maintaining airport runways integrity and avoiding cases of water ingress on them.

- Nevosafe™ is a rebar protection system that helps to improve safety at construction sites by covering exposed rebar ends. They minimise the occurrence of accidents in construction areas, increasing safety among workers. This system is important in busy construction areas like airports where safety is paramount to minimise risks.

- Denso Tape is used for anti-corrosive and sealing applications, particularly for joints and pipes. It is very sticky, water-proof and can form a good cover against various slight influences. This tape is important for airport construction concerning preserving underground and overhead utilities.

- Sealants are used to fill and seal joints and cracks found in concrete structures. They offer an elastic shield that will not allow water, air and debris to compromise the concrete. Sealants are crucial in constructing airports they help maintain the strength of the construction of runways and pavements.

- Epoxy grout such as Dayton J55 is applied in fixing and sticking in concrete structures. It gives high strength and chemical resistance making it suitable for high-stress applications such as airport runways. Epoxy ensures that the concerned concrete elements are well bonded and also resistant.

- Curing compounds are applied to newly placed concrete to facilitate the retention of the concrete cure. This helps in achieving optimal strength and durability. In airport construction, curing compounds help achieve the required hardness on the runways and pavements and adjust their wearing properties.

- Concrete spacers are used to maintain the correct positioning of rebar in concrete structures. They ensure that the reinforcement is properly embedded in the concrete, which is critical for the structural integrity of runways. Proper use of spacers helps in achieving uniform coverage and preventing corrosion.

- Builders Film is applied where an extra layer is required to protect the structure from moisture penetration. It prevents moisture ingress and acts as a shield against dust and debris. In airport construction, Builders Film is critical to protecting materials and ensuring a clean and controlled environment.

Case Study: Japan’s Kansai International Airport

In the 1980s, Japan faced a unique challenge in the Osaka Prefecture—building an airport in a space-constrained, mountainous region. The solution? Construct an artificial island. This colossal project started in 1987 and was accomplished by thousands of workers in three years including an island and bridge to this island. However, it was losing ground – the island’s supporting columns had to be reinforced.

This monumental engineering task became the now famous Kansai International Airport built on adjustable pillars with sliding joints, which is very effective for an earthquake-prone area. Surprisingly, there was not a single report of damage to the airport during the Kobe earthquake in 1995, proving the efficiency of these measures.

Concrete Pillars in Madeira

Another marvel of engineering can be noted to be the Madeira Airport in Portugal. Taking its place among the world’s most dangerous airports because of the geographical characteristics of the site, there was a massive renovation in 2003. The extension of the runway in built on 180 concrete piles and some of the piles have heights of up to 70 meters to cater for height differences all over the region. While such a construction appears to be rather intimidating, it is perfectly safe, and the construction proves how crucial inventive engineering is at this stage.

Conclusion

Airports are often the most practical or comfortable means of accessing remote locations. In Australia, where space can be a limiting factor, the ingenuity of engineers and builders is critical. At Danterr, we are ready to back up such projects by providing our best products and knowledge. Our mission is to be one of the leaders in the future of airport and runway construction in Australia, contributing to developing infrastructure that meets the growing demands of air travel and defence needs.

Explore our comprehensive range of products and services, and discover how Danterr can support your next airport construction project. Together, we can build the future of aviation infrastructure in Australia.

Contact Danterr today!

📞: 1800 262 383

📧: sales@danterr.com

Frequently Asked Questions:

Building airports in Australia involves navigating diverse geographical terrains, from coastal regions to outback deserts, which can impact construction methods and materials. Urban locations often face space constraints and regulatory hurdles that require innovative engineering solutions. Additionally, environmental considerations, such as minimising the impact on local ecosystems and adhering to sustainability standards, add complexity to the projects.

Dowels are critical components in airport runway construction as they maintain load transfer across concrete joints, ensuring that slabs remain aligned and stable. This prevents differential settlement, which can cause cracking and surface irregularities. By allowing controlled horizontal movement, dowels help runways withstand the heavy loads and constant traffic of aircraft, contributing to their durability and longevity.

FutureFlex™ Expansion Foam is designed to absorb the expansion and contraction forces caused by temperature fluctuations and the heavy loads typical in airport environments. This foam ensures that joints remain flexible and intact, preventing cracks and structural damage. It helps maintain the runway’s smooth surface, which is crucial for the safety and efficiency of airport operations.

Hydrotite is a hydrophilic waterstop that plays a vital role in waterproofing concrete structures. It expands upon contact with water, sealing joints and cracks effectively. This feature is crucial in preventing water ingress, which can compromise the structural integrity of airport runways and pavements. Hydrotite ensures that the infrastructure remains durable and resistant to water damage.

Sealants are essential in airport construction for filling and sealing joints and cracks in concrete structures. They provide a flexible, impenetrable barrier that prevents water, air, and debris from infiltrating the concrete, which can lead to damage and deterioration. In the harsh Australian climate, using high-quality sealants ensures the long-term durability and safety of airport runways and pavements.

Builders Film is a moisture barrier and protective layer in construction projects. It prevents moisture ingress, which can weaken concrete and other building materials. Additionally, it acts as a shield against dust and debris, maintaining a clean and controlled environment during construction. This protection is crucial in large-scale projects like airports, where maintaining material integrity and a clean work site are essential for successful completion.

Airport construction in urban areas faces significant space constraints and must navigate complex regulatory environments. Innovative design solutions are often required to maximise available space and disruption to surrounding communities. In contrast, rural airport projects may have more straightforward site preparation but face logistical challenges due to remote locations, including transportation of materials and accessibility for construction crews.

Using high-quality materials is crucial in airport construction to ensure safety, durability, and longevity. Airports experience heavy use and must withstand extreme weather conditions and constant stress from aircraft operations. High-quality materials, like those provided by Danterr, help prevent future maintenance issues, reduce downtime, and ensure the smooth, uninterrupted operation of airport facilities.

The time it takes to build an airport can vary significantly depending on the project’s size, complexity, and location. On average, constructing a new airport can take between 5 to 10 years. This timeframe includes planning, design, regulatory approvals, site preparation, construction, and testing phases. Major expansions or upgrades to existing airports may take less time, typically around 3 to 5 years.

The cost of building an airport can range widely based on factors such as size, location, and the level of infrastructure required. Small regional airports cost between $50 million to $100 million. Larger international airports with extensive facilities can cost several billion dollars. For example, recent major airport projects around the world have seen costs ranging from $5 billion to $15 billion or more. In Australia, the cost will also be influenced by local construction costs, regulatory requirements, and specific site conditions.

Stay Updated with Danterr!

Subscribe to Our Newsletter for the Latest in Construction Solutions