The Problem – From a more personal view

As I walked past the fancy new estate in my hometown on the Great Ocean Road, I noticed little white polystyrene balls spread from vacant, to working and finished housing blocks. I wondered how a building company could, in good conscience, use this material adjacent to a national heritage listed, seaside-hugging highway.

-A highway that’s sheer beauty attracts “around $14 million in direct revenue annually” to the coastal towns and 3-4 types of whale from Antartica for calving every year.

Working in the concrete accessories world, I was aware of the cost advantages of polystyrene waffle pods and chalked it up to lack of product alternative but to my surprise, soon after my walk, I learned of a new product (and partnership) for Danterr, the QPOD flooring foundation. But it wasn’t until I saw the product in person, in that same fancy new estate, that I realised the relief and pride I had being part of the change for better, in the construction industry.

Wondering about their journey from prototype to finished product, I connected with Eddie from QPOD to discuss the creation of their eco-friendly alternative.

QPOD POUR ON GREAT OCEAN ROAD

QPOD™, The story of how it came to be

One afternoon in 2017 Steve and Eddie Crawshaw, the PSI team and a business mentor sat down to discuss the ways in which they could bring more value to their brand and products. The result, one of the worlds first 100% recycled plastic eco pod – a level up from the other pod manufacturers, who were only using a small % of recycled plastics.

With no background in the commercial housing industry, the team set about designing a concept for a recycled plastic void filler that would be better than the international equivalents. But how could this be achieved?

“The question was, what can we cut out of the process, to save time for the builder?” Eddie said

Reflecting on this, the PSI team came up with the idea for an inbuilt patented barchair that not only would save time for the builder but help them stand out. Already manufactures of recycled plastics and injection molded products, the team were able to make their pod at various stages throughout the design process with 3D modelling, including the little features like this bar chair.

It was from these models they drew inspiration for future designs, realizing early on the need for certification, and endorsement of their void filler.

DESIGN CONCEPTS AND DRAWINGS

Making Connections

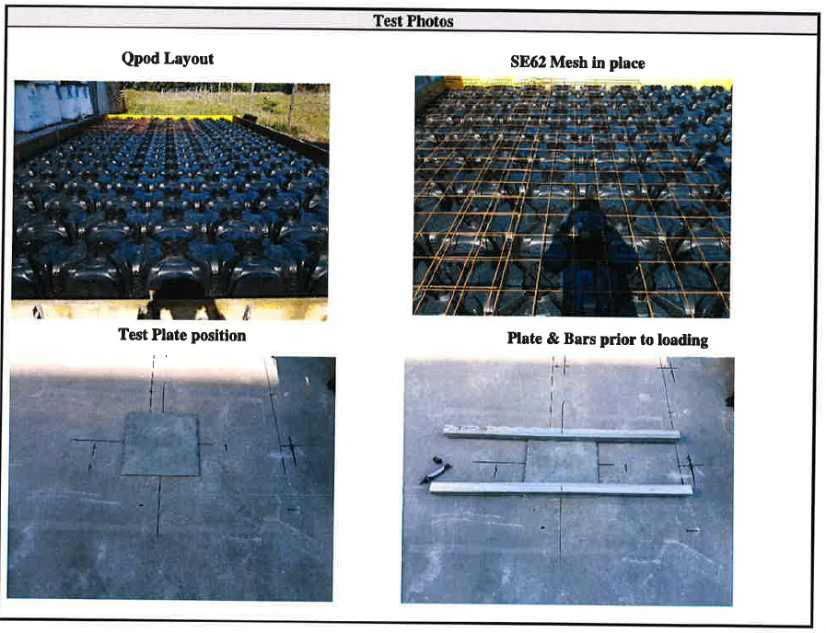

In 2018 the team started various testing of the pods to access their ease of use and general ability.

“We were working with Allied concrete, who also had their own team of engineers, as we knew we needed an influential partner who would be able to endorse the product when finished,” said Eddie.

The team then worked on gaining BRANZ appraisal and finding a company to pour a slab with.

“We needed to show the end user that it was dead easy” Eddie said.

2018 TESTING IN NEW ZEALAND

While the search for an initial client to build with was met with a few setbacks, the team eventually found a company.

Much of the feedback from the first few pours cemented that the product was easy to walk on, easy to attach steel mesh too and easy to transport to site. In fact, you could say the feedback was that QPOD flooring foundation was dead easy.

To showcase this material, the team decided to have BBQs and open days at site. This worked well, creating a bond between the team and the new builds and is still carried out across NZ.

DANTERR QPOD™ POUR

The Product as we know it

A take on the traditional waffle pod system, the QPOD™ raft is a flooring foundation used to support the pouring of a concrete slab. It is placed on the vacant ground before the concrete is poured and acts as a void filler.

The product features a stool-like design with a hollow interior for easy stacking, significant transport savings and in slab utility pipe coverage. A single pod is tessellated by four with easy clips that attach each four pods, to four more and so on, until the end caps are needed to close the design.

There is no limit to the size of the raft configuration and all QPOD™’s feature a built in barchair, further easing the process and adding value for the buyer.

Future Goals?

“Our future goal would be to eliminate polystyrene by increasing our market share and through design perfections that make it easy for the homeowner or construction company to lay down their floor.

It is an education process, if we can do that in New Zealand and we can do that in Australia, we can do that anywhere.” -Eddie Crawshaw

For enquiries about this product please contact DANTERR directly or indirectly through the QPOD flooring foundation product page, or our contact page here.