At Danterr, we understand that in the evolving realm of construction, it’s essential to provide professionals with superior alternatives that drive success in their projects. Our range of reinforcing solutions goes beyond the conventional, offering both versatility and unmatched quality.

Deformed Reinforcing Bar

Deformed bars, or rebars as they are colloquially known, are the backbone of many structures. Characterised by their ribbed surface, they provide the necessary grip that binds them securely to concrete, ensuring structural stability. These Class N (normal ductility) reinforcing bars are perfectly tailored for diverse applications, such as reinforced concrete slabs, prefabricated beams, and columns, meeting all relevant Australian standards.

Benefits:

- Durability: With a consistent track record, these bars offer enduring strength, ensuring that structures remain solid and stable for years to come.

- Versatility: Suitable for a wide range of applications, catering to the varied demands of the construction industry.

- Standards Compliant: Meeting and often surpassing all the required Australian standards, guaranteeing quality and reliability.

Bulk Orders & Custom Requirements

For those tackling large-scale projects, Danterr stands ready to manage both bulk orders and custom requirements. Discuss your needs with our experts to secure the best reinforcing solution tailored to your endeavour. Contact us directly at 1800 262 383 or drop us an email at sales@danterr.com.

Beyond the Traditional: Exploring Alternatives to the Deformed Reinforcing Bar

In construction, the deformed bar has always been a go-to. But as building methods grow and change, there’s a bigger push for special products that fit different project needs. At Danterr, we’ve expanded our range to include the Stainless Steel Reinforcing Bar, the Galvanised Reinforcing Bar and the Fibreglass Reinforcing Bar. Each of these options can often do more than the usual rebars, giving architects and builders more choices for their projects. Let’s take a closer look at these advanced solutions and see how they can benefit today’s construction tasks.

Stainless Steel Reinforcing Bar

Engineered for settings that demand superior corrosion resistance, stainless steel reinforcing bars not only enhance the structure’s longevity but also its aesthetic appeal. Made with precision, they’re the answer to challenging environments where traditional steel might falter.

Benefits:

- Corrosion Resistance: Stands strong against environmental challenges, ensuring long-lasting structures.

- Aesthetic Appeal: Offers a cleaner look, elevating the overall visual appeal of projects.

- Cost-Effective: In the long run, reduced maintenance and repair needs can lead to significant cost savings.

Galvanised Reinforcing Bar

Undergoing an intensive hot-dip galvanising process, this bar exemplifies Danterr’s commitment to exceptional quality. It promises unmatched resistance against the persistent threat of corrosion and rust, setting a new standard for reinforcement in the industry.

Benefits:

- Enhanced Durability: With its rust-resistant properties, this bar ensures extended life for structures.

- Versatility: Its robust nature makes it perfect for a plethora of applications.

- Safety: The galvanising process reduces the risk of premature structural failure due to rust.

Fibreglass Reinforcing Bar (GFRP)

A marvel of modern engineering, GFRP emerges as a high-strength, corrosion-resistant alternative to conventional steel. Its unique composition offers extended structural life, making it an asset for various innovative projects.

Benefits:

- Extended Lifespan: GFRP’s corrosion-resistant nature promises a longer structural life.

- Safety: The risk of repetitive lifting injuries is diminished thanks to its lightweight property.

- Specialised Applications: Its electrical non-conductivity makes it perfect for projects like light rail or tram slabs.

Introducing Danterr’s Mesh Reinforcements for Modern Construction

In construction, while bars have long been the go-to for reinforcement, mesh products are gaining ground. They offer both flexibility and strength, helping spread loads evenly across large areas. At Danterr, we’re proud to offer three types of mesh reinforcements: Stainless Steel Reinforcing Mesh, Galvanised Reinforcing Mesh and Fibreglass Reinforcing Mesh. Each one has its own set of benefits and is crafted to meet the needs of today’s building projects. Let’s take a closer look at how these mesh products are making a difference in modern construction.

Stainless Steel Reinforcing Mesh

An epitome of precision and strength, the Stainless Steel Reinforcing Mesh is designed to impart tensile strength to concrete, enhancing structural longevity and minimising the risk of cracks.

Benefits:

- Robustness: Provides enhanced tensile strength, ensuring structures withstand various stresses.

- Durability: With high resistance to corrosion, it promises a longer lifespan for constructions.

- Aesthetic Appeal: Lends a refined look to the structure, ensuring both strength and style.

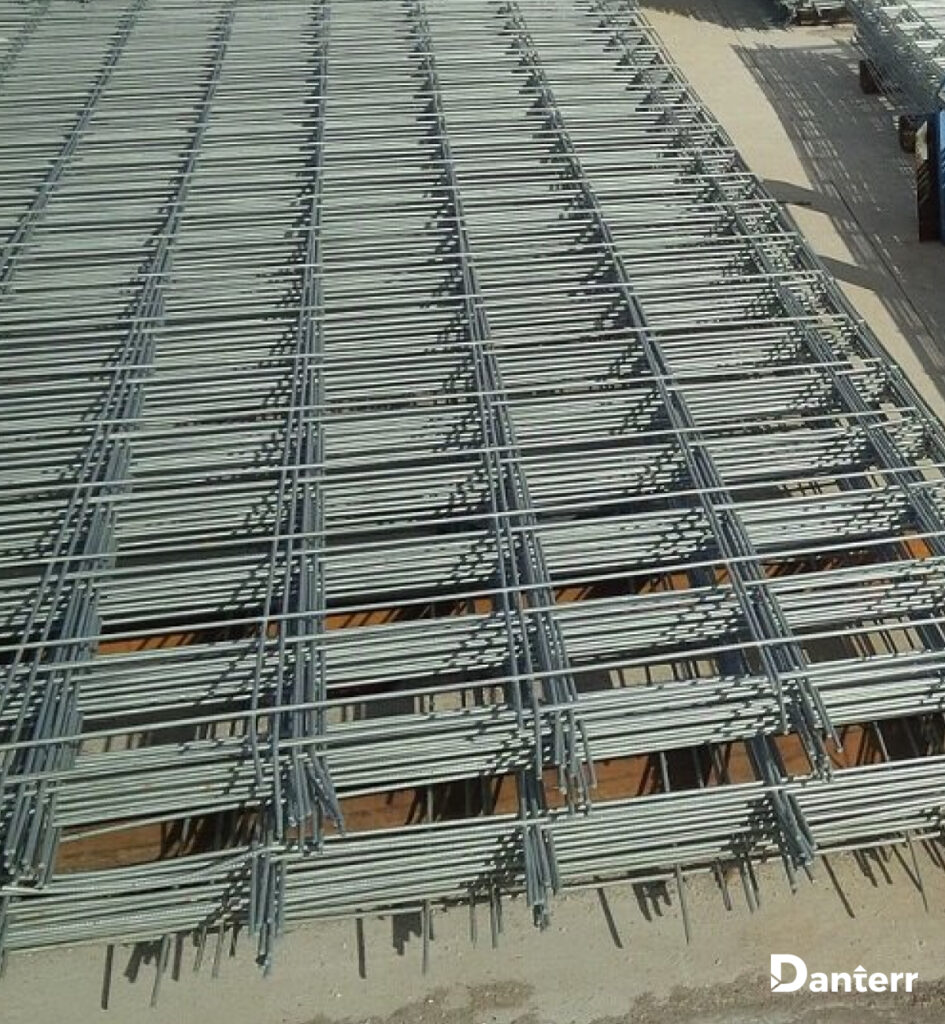

Galvanised Reinforcing Mesh

Embodying Danterr’s promise of quality, the Galvanised Reinforcing Mesh stands as a bulwark against the elements. Tailored for modern construction scenarios, its corrosion-resistant properties ensure enduring infrastructure across a plethora of applications.

Benefits:

- Longevity: The galvanised coating ensures the mesh remains rust-free for extended periods, preserving structural integrity.

- Versatility: Designed to be adaptable, catering to a broad spectrum of construction needs.

- Safety: Offers consistent reinforcement, reducing the risk of structural anomalies.

Fibreglass Reinforcing Mesh

Treading the path of innovation, Fibreglass Reinforcing Mesh emerges as a vanguard in reinforcement. With inherent properties like electrical non-conductivity and non-magnetism, this mesh is more than just reinforcement; it’s a strategic choice for specialised projects.

Benefits:

- Adaptability: Tailored for critical undertakings, it ensures the longevity and integrity of a variety of structures.

- Safety: The non-conductive nature makes it optimal for projects near electrical installations.

- Specialised Utility: Perfect for niche projects such as light rail or tram slabs where traditional metals could interfere with operations.

At Danterr, we’re not just about offering products; we’re about crafting solutions tailored to your construction needs. Whether it’s our range of reinforcing bars or meshes, we’ve got you covered!

Need bulk requirements? We’re here to help.

? Email us at sales@danterr.com

☎ Or give us a call at 1800 262 383.

Frequently Asked Questions:

Danterr’s deformed reinforcing bars, often referred to as rebars, are integral to a wide range of concrete structures. Their primary use is to provide tensile strength to concrete, which naturally has high compressive strength but is weak in tension. The ribbed surface of these bars ensures a strong bond with the concrete, preventing slippage and enhancing the structure’s overall stability. They are commonly used in constructing reinforced concrete slabs, beams, and columns, and are essential for residential and commercial projects. Meeting all relevant Australian standards, Danterr’s deformed reinforcing bars ensure compliance and reliability across diverse construction applications.

Stainless steel reinforcing bars offer several key benefits that make them attractive for certain construction projects. First, their superior corrosion resistance makes them ideal for use in environments prone to moisture and chemical exposure, such as coastal areas and industrial facilities. This corrosion resistance extends the lifespan of structures, reducing the need for maintenance and repairs over time. Additionally, stainless steel has an aesthetic appeal due to its clean and modern look, which can enhance the visual quality of exposed structural elements. Lastly, while the initial cost of stainless steel reinforcing bars may be higher than traditional steel, the long-term savings from reduced maintenance and increased durability can make them a cost-effective option in the long run.

Galvanised reinforcing bars undergo a hot-dip galvanising process where they are coated with a layer of zinc. This zinc coating is a barrier that protects the steel from corrosive elements such as water and chemicals. The galvanisation process significantly enhances the durability of the reinforcing bars by preventing rust and corrosion, which are common causes of structural failure. This makes galvanised reinforcing bars particularly suitable for harsh environments, such as marine or industrial settings. The improved durability of these bars ensures that structures remain strong and stable for extended periods, reducing the need for frequent repairs and enhancing overall safety.

Glass Fibre Reinforced Polymer (GFRP) rebar is a type of reinforcing bar made from a composite material of glass fibres embedded in a polymer matrix. GFRP rebar is highly valued for its non-corrosive properties, it is an excellent choice for environments where traditional steel rebar would be susceptible to corrosion, such as marine structures, bridges, and tunnels. In addition to its corrosion resistance, GFRP rebar is lightweight, which reduces transportation and handling costs, and its high tensile strength allows for less material without compromising structural integrity. GFRP rebar is also electrically non-conductive, making it suitable for use in areas near sensitive electronic equipment.

Danterr’s fibreglass reinforcing mesh is designed to offer high tensile strength and excellent corrosion resistance, making it a robust alternative to traditional steel mesh. Its lightweight nature simplifies transportation and handling on construction sites, reducing the need for heavy lifting equipment and the associated risk of injuries. The fibreglass mesh is also flexible, allowing it to be easily shaped and cut to fit various structural needs. These properties make it ideal for reinforcing large areas such as slabs, foundations, and precast products. The corrosion resistance of the fibreglass mesh ensures long-term durability, especially in environments exposed to moisture and chemicals.

Concrete jointing systems are crucial in construction because they manage the natural movements of concrete, such as expansion and contraction due to temperature changes and drying shrinkage. Without proper jointing, these movements can lead to unsightly and potentially dangerous cracks. Concrete jointing systems, such as expansion joints, contraction joints, and construction joints, help control where these cracks occur, ensuring they do not compromise the structural integrity of the concrete. By managing these movements, jointing systems enhance the durability and lifespan of concrete structures, maintaining their safety and aesthetic appeal over time.

Nevosafe™ caps are designed to enhance safety on construction sites by covering the protruding ends of reinforcing bars (rebar). These caps provide protection against potential impalement injuries, which are a significant hazard in construction environments. Nevosafe™ caps are made from durable, weather-resistant plastic and are highly visible, ensuring they are easily identifiable even in low-light conditions. They can be securely attached to rebar of various diameters, providing reliable protection for both horizontal and vertical installations. Additionally, Nevosafe™ caps are reusable, making them a cost-effective safety solution for multiple projects.

Fibreglass dowels, made from Glass Fibre Reinforced Polymer (GFRP), offer several advantages over traditional steel dowels. Their non-corrosive nature ensures they do not contribute to joint weakening over time, a common issue with steel dowels in corrosive environments. The lower stiffness of fibreglass dowels compared to steel reduces stress concentrations in the concrete, which can help prolong the life of the structure. Additionally, fibreglass dowels are electromagnetically transparent, making them suitable for use in areas with sensitive electronic equipment, such as near-induction sensors or medical devices. These properties make fibreglass dowels a reliable and durable option for load transfer in concrete slabs.

Fibreglass reinforcing bars (GFRP) offer several benefits over traditional steel reinforcing bars. The most significant advantage is their corrosion resistance, which is a common issue with steel rebar, especially in environments exposed to moisture, chemicals, or salt water. This corrosion resistance significantly extends the lifespan of structures reinforced with GFRP bars. Additionally, GFRP bars are lightweight, reducing transportation and handling costs and minimising the risk of injuries on construction sites. They also have a high tensile strength, allowing less material while maintaining structural integrity. Furthermore, GFRP bars are non-conductive, making them suitable for use in areas where electromagnetic interference must be avoided.

Using high-quality reinforcing products is crucial in construction to ensure the longevity, safety, and performance of structures. Quality reinforcing products, such as those offered by Danterr, meet or exceed industry standards, providing reliable tensile strength and durability. These products help prevent structural failures, reduce maintenance costs, and enhance the overall safety of buildings and infrastructure. High-quality reinforcement also ensures that structures can withstand environmental stresses, such as load, temperature changes, and chemical exposure, maintaining their integrity over time. By choosing quality reinforcing products, construction professionals can ensure the success and longevity of their projects, ultimately leading to safer and more sustainable built environments.

Stay Updated with Danterr!

Subscribe to Our Newsletter for the Latest in Construction Solutions