Concrete Jointing Systems play a pivotal role in modern construction, addressing the inherent challenges of concrete’s inability to stretch or bend without cracking. Despite concrete’s unparalleled strength and durability, its natural movements due to temperature changes and drying shrinkage necessitate these innovative systems. Essential for preventing cracks and ensuring the structural integrity of concrete slabs, concrete jointing systems are key to constructing durable, long-lasting structures. Join us as we explore the types, functions, and cutting-edge solutions in the realm of concrete jointing, highlighting Danterr’s expertise and comprehensive product range designed to meet these critical construction needs.

Understanding Concrete Jointing Systems

What Are Concrete Jointing Systems?

Concrete jointing systems are specialised solutions designed to manage concrete’s natural expansion and contraction, minimising the risk of cracks and damage. These systems are vital in construction projects, serving as a preventative measure against the environmental stressors that affect concrete over time.

The Benefits of Using Concrete Jointing Systems

- Durability: Concrete jointing systems are integral to extending the service life of concrete surfaces. By accommodating natural movements due to temperature changes and load stress, these systems prevent the formation of unsightly and potentially damaging cracks. This ensures that concrete structures remain intact and functional for decades, resisting wear and tear under various environmental conditions.

- Safety: Safety in construction and structural integrity go hand in hand with the use of concrete jointing systems. By preventing cracks and uneven surfaces, these systems significantly reduce the risk of tripping hazards and structural failures. This is particularly crucial in public spaces and industrial environments where safety is paramount. A well-implemented jointing system contributes to the overall stability of concrete structures, offering peace of mind and protection for users.

- Cost-Efficiency: Investing in concrete jointing systems results in substantial long-term savings. By minimising the need for repairs and maintenance, these systems ensure that the costs associated with fixing cracks, uneven surfaces, and other structural issues are significantly reduced. This preventative approach to concrete maintenance means resources can be allocated more efficiently, avoiding the unforeseen expenses that come with emergency repairs.

- Aesthetic Integrity: Concrete jointing systems play a crucial role in maintaining the aesthetic appeal of concrete installations. By controlling where and how concrete cracks, jointing systems ensure that surfaces remain visually pleasing. This is particularly important for architectural and decorative concrete projects, where appearance is as important as functionality. A well-designed jointing system preserves the intended look of concrete surfaces, contributing to the overall beauty of the built environment.

Types of Concrete Jointing Systems

- Expansion Joints: Expansion joints are critical in accommodating the thermal expansion and contraction of concrete structures. These joints are placed between concrete slabs and other parts of a structure to allow for movement without causing damage. By absorbing the expansion and contraction, expansion joints prevent the development of cracks and structural stress, ensuring the integrity of roads, bridges, buildings, and sidewalks.

- Contraction Joints: Contraction joints, also known as control joints, are strategically placed to create weakened planes in the concrete where cracks can occur in a controlled manner. These joints are essential for dealing with concrete shrinkage as it cures and dries, minimising random cracking by directing it along the joint. For floors, walls, and pavements, contraction joints are indispensable for maintaining surface integrity.

- Construction Joints: Construction joints are necessary where two consecutive placements of concrete meet. They are used to join new concrete work to existing or hardened concrete, ensuring continuity and structural integrity. These joints are crucial in phased construction projects, allowing for the sequential completion of sections. Properly designed and placed construction joints ensure that the segments of concrete work together as a single unit, despite being poured at different times.

- Isolation Joints: Isolation joints, also known as expansion joints, are used to separate concrete slabs from other elements of the structure, such as walls, columns, or footings. These joints allow independent movement between the adjoining parts, preventing stress and cracking that could arise from the concrete’s expansion and contraction. Isolation joints are essential for preserving the structural integrity and longevity of both the concrete slabs and the adjacent elements.

Danterr’s Range of Concrete Jointing Systems

At Danterr, our dedication to innovation and quality drives us to offer a comprehensive suite of concrete jointing systems designed to address the varied needs of contemporary construction projects. Our tailored solutions ensure durability, safety, and efficiency, making us a trusted partner in construction endeavors. Here’s an in-depth look at our diverse product range:

Bitumen Impregnated Fibre Board

Danterr’s Bitumen Impregnated Fibre Board category, highlighted by our VECTORFILL™ product, offers a specialized solution for expansion joint filling in a variety of concrete constructions. Ideal for applications requiring resilience and adaptability, VECTORFILL™ is the material of choice for engineers and construction professionals aiming to enhance the longevity and functionality of their projects.

VECTORFILL™

VECTORFILL™ stands as Danterr’s premium Bitumen Impregnated Fibreboard, designed specifically to address the needs of in-situ and pre-cast concrete constructions. Its versatility makes it suitable for a wide range of applications, including concrete pavements, roads, runways, and areas with high pedestrian traffic. Manufactured from high-quality, slow maturing fibres impregnated with bitumen, VECTORFILL™ offers a compressible, non-extruding board solution that excels in footpath, paving, and runway applications.

Ideal for filling expansion joints, VECTORFILL™ ensures seamless integration against existing concrete or adjacent structures, supporting concrete’s integrity through all phases of construction and use. Its ability to withstand repeated expansion and compression cycles, coupled with low moisture absorption and temperature resilience, underscores its value in any construction project seeking durability and maintenance ease. VECTORFILL™’s advantages include its exceptional durability, ease of handling, and adaptability to various sizes, making it an indispensable asset for concrete installations demanding high performance and longevity.

Dowels

At Danterr, we specialize in providing a diverse array of dowel solutions tailored to the dynamic needs of the construction industry. Our product range encompasses Galvanised Dowels, Stainless Steel Dowels, and Fibreglass (GFRP) Dowels, each designed to offer superior load transfer, alignment, and resistance to environmental factors. Alongside our traditional dowel offerings, we feature innovative systems like Flanged Dowel Boxes and Speed Sleeves, which streamline the installation process and enhance the functionality of concrete joints. Whether for industrial applications, commercial buildings, or infrastructure projects, Danterr’s dowels are engineered to improve construction outcomes by facilitating seamless load distribution, minimizing cracking potential, and accommodating concrete’s natural movements. This comprehensive suite of dowel products represents our commitment to quality, innovation, and the success of construction projects worldwide.

- Dowels: Used primarily in slab-on-grade joints, our concrete dowels facilitate the transfer of load across a joint, ensuring alignment and reducing stress on the concrete. This results in smoother surfaces and longer-lasting concrete installations.

- Connolly Crack Inducers: Connolly Crack Inducers are ingeniously designed to control cracking at specific points within concrete slabs. Made from inflexible PVC, these inducers are positioned with supplied pins, typically used below Dowel Cradles. They facilitate controlled cracking, either in conjunction with a saw cut or Crack Inducer at the slab’s surface, ensuring the integrity and longevity of the concrete structure.

- Dowel Cradles: Dowel Cradles represent a preeminent solution in load transfer systems for contraction joints. Prefabricated for precise height and center placement, Dowel Cradles are left in place before the concrete pour, ensuring seamless load transfer and minimizing shrinkage cracks. The system comprises a wire cradle and load transfer apparatus, perfectly aligning and suspending dowels and sleeves for exact placement. This meticulous arrangement prevents vertical displacement of the slab, significantly enhancing structural integrity.

- Galvanised Dowels: Our Galvanised Dowels combine durability with cost-effectiveness, ideal for maintaining structural integrity under harsh conditions. The hot-dip galvanizing process coats each dowel in zinc, offering robust protection against corrosion. This economical option ensures long-term savings by reducing maintenance and replacement needs.

- Stainless Steel Dowels: Stainless Steel Dowels are distinguished by their exceptional strength and corrosion resistance. The addition of chromium to stainless steel forms a protective barrier against environmental factors, making these dowels a reliable choice for critical applications where durability is paramount.

- Fibreglass (GFRP) Dowels: For projects requiring lightweight, corrosion-resistant solutions, our Fibreglass Dowels are unparalleled. These dowels are a quarter the weight of steel alternatives and provide significant advantages in terms of ease of handling, installation, and thermal insulation. Their non-corrosive, non-magnetic properties make them perfect for projects necessitating electromagnetic neutrality and minimal thermal bridging.

- Expansion Caps: Expansion Caps are designed to cap round dowels in concrete joints, featuring an internal mould fluting that compresses with dowel movement to ensure the cap remains secure. Accommodating standard diameters of round dowels in just two sizes – 10mm to 16mm, and 16mm to 50mm – these caps are essential for maintaining joint integrity and function.

- Heat Shrink Sleeves: Heat Shrink Sleeves offer a convenient and effective alternative to greasing or taping dowel bars, suitable for all shapes and sizes of dowels. These sleeves limit compression and ensure the seamless movement of dowels within concrete joints, contributing to the overall durability and functionality of the installation.

Expansion Foam

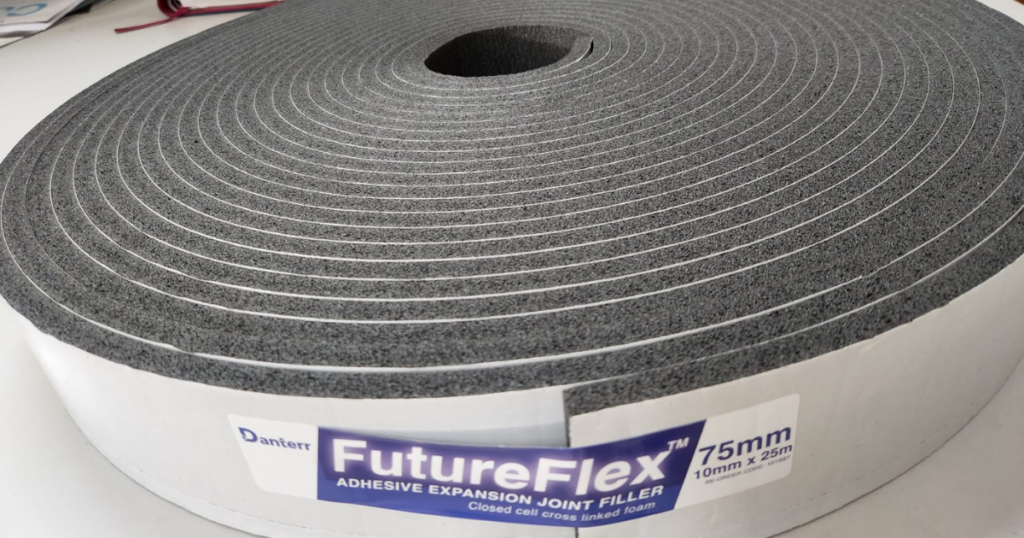

Danterr’s Expansion Foam lineup, including FutureFlex™ and FutureFlex™ Sheets, offers superior expansion and isolation solutions for construction. Crafted with cutting-edge technology, these products ensure flexibility, water resistance, and durability across diverse applications, from infrastructure to water management projects.

- FutureFlex™: Our FutureFlex™ is a standout cross-linked, non-absorbent, closed-cell, polyethylene expansion joint filler board. It’s specifically designed for excellence in both expansion and isolation joint applications, offering unparalleled performance in concrete and other masonry structures. With its non-absorbent properties and remarkable flexibility, FutureFlex™ is perfectly suited for use in structures exposed to various water types, including potable, salt, chlorine, and sewerage water. This makes it an ideal choice for water-retaining or excluding structures, ensuring long-lasting durability and integrity.

- FutureFlex™ Sheets: FutureFlex™ Sheets elevate the standard for joint filling materials, employing cutting-edge closed-cell polyethylene foam technology. These sheets are tailored for challenging and critical projects such as dams, port quays, underground flood defence projects, road and rail tunnels, hydropower stations, airports, bridges, and mass-concrete sealing joint projects. Their versatility and superior performance in sealing joint applications establish them as an indispensable resource in the construction industry, delivering reliability and efficacy across a multitude of demanding environments.

Expansion Joint Systems

Danterr’s Expansion Joint Systems range is designed to provide comprehensive and customizable solutions for managing concrete expansion and contraction. Catering to a variety of construction needs, our systems, including Connolly Expansion Joints and Custom Expansion Joints, are developed to ensure precision, durability, and seamless integration into any project.

- Connolly Expansion Joints: Connolly Expansion Joints offer a complete system for accommodating slab movements, including a 1 x Expansion Joint with 10mm thick closed-cell PE foam. Available in 3m lengths for slabs of different heights, each set comes with dowel bars, dowel sleeves, pegs and wedges, all numbered and sized for exact alignment and effective stress management.

- Custom Expansion Joints: Danterr’s Custom Expansion Joints are crafted to exceed the typical 200mm industry standards, providing bespoke solutions for unique project requirements. With the capability to be customized in any finish, our joints ensure perfect fit and optimal performance for complex construction demands.

Fire Rated

Danterr’s Fire Rated product line is meticulously engineered to enhance the fire resistance of construction joints and penetrations, providing critical safety measures for buildings. Including Fire Rated IBS Foam and Fire Rated Sealants, our solutions are designed for compliance and protection against fire, ensuring the structural integrity and safety of construction projects under the most demanding conditions.

- Fire Rated IBS Foam: Our Fire Rated IBS Foam is a flexible, fire-resistant foam strip, essential for maintaining fire resistance in joints and service penetrations within floors and walls. It’s an effective alternative to fire-resistant sealant, ensuring compliance and safety in critical applications.

- Fire Rated Sealants: Danterr’s Fire Rated Sealants are intumescent, low modulus, one-component, Class-A polyurethane sealants. Upon curing, they form a tough, flexible fire-rated seal capable of cyclic expansion and compression, maintaining integrity under extreme conditions, including exposure to weathering and environmental pollutants.

Joint Sealants

Our comprehensive range of joint sealants provides flexibility and durability, catering to various construction needs:

- Backing Rod: A compressible, closed-cell polyolefin foam tube with an outer skin, used as backing for cold-applied sealants in expansion/construction joints and building seal applications. It ensures a uniform depth for sealant application, enhancing the effectiveness of joint sealing.

- Backing Rod Tool: This tool revolutionizes the placement of foam backer rods in caulk joints, ensuring rapid, consistent, and puncture-free placement. Adjustable depth and multiple wheel widths accommodate diverse project requirements, making it an indispensable tool for achieving professional results.

- Bond Breaking Tape: Danterr’s Bond Breaker Tape is a black self-adhesive polyethylene tape, adept at adapting to asymmetrical surfaces. It plays a critical role in ensuring the correct sealant depth and preventing three-sided adhesion, vital for effective joint sealing.

- Fulaflex 550 PU Sealant: A one-component moisture-curing low modulus Class A polyurethane sealant, Fulaflex 550 PU LM offers exceptional joint movement capabilities, forming a flexible, durable, and weather-resistant seal.

- Fulaflex 570 FC PU Sealant: Developed specifically for concrete and masonry, Fulaflex 570FC PU is a fast-cure polyurethane adhesive/sealant boasting strong adhesion and weather resistance.

- Fulaflex 650 FC Sealant: A high-performance, 1-part hybrid moisture curing sealant/adhesive, Fulaflex 650FC is designed for high-traffic areas, curing to form a tough, elastic, and weatherproof seal.

- Masking Tape: Designed for the construction industry, our 48 mm x 50 m Masking Tape offers superior adhesion and reliability for various applications, from protective masking to aiding painting tasks.

- Sealant Gun: Tailored for 600ml adhesive sausages, our Sealant Gun combines robust construction with a user-friendly design, ensuring efficient and smooth application for all adhesive tasks.

Key Joint Systems

Danterr’s Key Joint Systems offer advanced solutions designed to manage concrete slab movements and load transfer with precision and reliability. Our range includes Key Joint Capping and Key Joints, each engineered to accommodate varying construction needs, from load qualification between slabs to the creation of recesses or joint fillers. Ideal for ensuring structural integrity and facilitating construction processes, these systems are essential for modern concrete installations.

- Key Joint Capping: Our Key Joint Capping enhances Key Joints by adding a top edge capping, creating a recess or allowing for a colour-coordinated joint filler. Available in standard 3mm recess, block 10mm recess, or the innovative permanent Rip-A-Strip Capping, this product offers versatility and functionality in finishing concrete slab edges.

- Key Joints: Key Joints form a crucial part of a metal joint system designed for transferring loads between adjacent slabs while permitting horizontal movement and minimizing differential deflection. Self-supporting and height-adjustable through a stake system, Key Joints are compatible with both temporary and permanent capping profiles. Sold in 3m lengths of varying heights, with stakes included for installation convenience, Key Joints provide a robust solution for concrete slab management. Capping and Rip-A-Strip are available separately to complement and complete the system.

Sleeves

Danterr’s Sleeves category is designed to streamline and enhance the durability of concrete joint and dowel installations. Featuring Flange Dowel Boxes, Speed Sleeve Nailing Plates, and Speed Sleeves, this range offers versatile, efficient solutions for both ground and elevated slabs, ensuring alignment, minimizing movement, and facilitating thermal expansion and contraction. Ideal for industrial and commercial projects, our Sleeves products simplify the construction process while maximizing structural integrity.

- Flange Dowel Boxes: Flange Dowel Boxes are multi-directional metal sleeves tailored for square dowels, offering a robust solution for managing concrete slab movements. Engineered for easy attachment to both metal and wooden formwork, these boxes allow for initial shrinkage, thermal expansion, contraction, and excess lateral movement between slab panels. With the capability to be customized to any specifications, Flange Dowel Boxes are essential for construction joints in a variety of slab applications.

- Speed Sleeve Nailing Plates: Designed to be nailed to the formwork and attached to Speed Sleeves, Speed Sleeve Nailing Plates ensure secure and precise placement. These plates can be removed and reused for subsequent concrete pours, providing a cost-effective and efficient solution for dowel installation.

- Speed Sleeves: Speed Sleeves offer a revolutionary method for using friction-cut round dowels without the need for drilling formwork or greasing dowels. By significantly reducing vertical movement at joints and potential joint damage, Speed Sleeves make dowel installation quick and easy. Available in standard sizes of 16mm, 20mm, 24mm, and 33mm, they are nailed to wooden form boards using an optional nailing plate (sold separately) or can be used with existing or epoxied dowels for repeated pours. Perfect for industrial-sized ground slabs with multiple joints, Speed Sleeves streamline the construction process while enhancing the durability and integrity of the concrete structure.

Nailing plates are available separately to complement the Speed Sleeves, providing a comprehensive solution for efficient and effective concrete joint management.

Tapes

Danterr’s Tapes range is meticulously developed to address a wide array of waterproofing and sealing needs in construction projects. From subterranean applications to above-ground repairs, our selection, including BITUTHENE® 3000 and 5000, Denso Tape, Duct Tape, and Gaffer Tape, ensures high performance, durability, and reliability.

- BITUTHENE® 3000: A self-adhesive, rubberized asphalt/polyethylene waterproofing membrane, BITUTHENE® 3000 is ideal for basements, substructures, plazas, and parking decks, ensuring effective moisture and water resistance in various applications.

- BITUTHENE® 5000: Bituthene® 5000 combines moisture and water-resistant rubberized asphalt with a puncture and heat-resistant polypropylene reinforcing mesh. It’s specifically designed for use beneath hot-applied asphalt concrete wearing courses.

- Denso Tape: Composed of a non-woven synthetic fabric carrier, fully impregnated with a neutral compound, Denso Tapes offer extreme temperature resistance, providing long-term corrosion protection to pipes, valves, and related surfaces.

- Duct Tape: Our duct tape is engineered for construction site durability, offering a strong grip for temporary wiring organization, joining plastic sheeting, and serving as a protective barrier against spills or debris. It’s a versatile tool for a myriad of temporary fixes and protective measures.

- Gaffer Tape: Danterr’s Gaffer Tape is a waterproof, high-strength cloth tape with aggressive adhesive properties, making it ideal for industrial maintenance, repairs, sealing, and binding. It ensures reliability and effectiveness in the toughest conditions.

Void Formers

Danterr’s Void Formers category, led by the innovative VoidX™, is engineered to address the challenges posed by Australia’s diverse geological conditions. Our solutions are designed to mitigate the risks associated with ground movement and soil instability, ensuring the structural integrity and longevity of concrete slabs in construction projects across varying terrains.

VOIDX™

VoidX™ represents a significant advancement in void-forming technology, tailored to protect concrete slabs against the dynamic and often unpredictable changes in the earth’s surface. Developed in response to Australian geological data, which highlights the unsuitability of certain areas for heavy structures due to soil movements and clay swellings, VoidX™ acts as a critical safeguard. It enables both negative and lateral movements by creating a strategic void between the ground and the slab, effectively managing naturally occurring earth functions. Featuring a degradable, sacrificial void form with an expanded paper honeycomb core, VoidX™ is designed to support construction traffic and the weight of wet concrete until it cures to self-supporting strength. Over time, it decomposes, leaving behind a void that separates slabs and beams from expansive soils, embodying an eco-friendly, high-capacity, and easy-to-install solution for modern construction challenges.

Conclusion

Concrete jointing systems are an indispensable part of modern construction, essential for maintaining the structural integrity, safety, and aesthetic appeal of concrete installations. Danterr’s comprehensive range of jointing solutions embodies our commitment to quality, innovation, and service excellence. By choosing Danterr, you ensure your projects stand the test of time, backed by the best in the industry.

Ready to Enhance Your Construction Project?

Explore our range of concrete jointing systems and discover how Danterr can elevate your construction standards. For more information or to request a quote, contact us today at 1800 262 383 or email sales@danterr.com. Let’s build a durable, safe, and aesthetically pleasing future together.

Frequently Asked Questions:

Concrete jointing systems are specialised designs and materials used to control the natural movements of concrete slabs, such as expansion, contraction, and cracking, ensuring the structural integrity and longevity of concrete installations.

Concrete joints are necessary because they help manage the expansion and contraction of concrete due to temperature changes, moisture, and other environmental factors, preventing uncontrolled cracking and structural damage.

The main types of concrete jointing systems include expansion joints, contraction joints, construction joints, and isolation joints, each serving a specific function in concrete construction.

Expansion joints work by creating a gap between concrete slabs or between a slab and another structure, allowing room for concrete to expand without causing damage or cracks due to thermal expansion.

Contraction joints and control joints refer to the same thing and are designed to control where concrete cracks occur as they contract during the curing process, ensuring that any cracking is predictable and aesthetically manageable.

Construction joints are placed where two pours of concrete meet, such as at the end of a day’s work or where a concrete structure is built in phases. They ensure continuity and structural integrity between separate sections of concrete.

Yes, isolation joints can prevent structural damage by separating a concrete slab from other parts of a structure, like walls or columns, allowing independent movement and minimising stress and cracking.

Concrete joints are designed based on factors such as the concrete mix, the expected temperature and moisture conditions, the size and shape of the concrete structure, and the anticipated loads and stresses on the concrete.

Contraction joints should be cut as soon as the concrete is firm enough to withstand the cutting process without ravelling, typically within 6 to 18 hours after finishing in standard conditions.

Maintaining concrete joints involves regular inspections to check for signs of wear or damage, cleaning out debris, and sealing or resealing joints with appropriate sealants to prevent water infiltration and erosion.

Stay Updated with Danterr!

Subscribe to Our Newsletter for the Latest in Construction Solutions