We told you this year is about becoming an industry expert. So, to honor our commitment we are going to get down and informational about Bituthene® Membrane.

For the layman, Bituthene® Membrane is only a product heard of when specified for a job. For the engineer, Bituthene® is a handy solution to a problem. For Danterr, Bituthene® is a high-volume enquiry. But one question remains the same:

What do I need to know about Bituthene®?

Well, there are the obvious differences -that we have talked about many times.

These include 5000 being a thicker and stronger tape, designed for use under hot applied asphalt – due to its rubberized asphalt surface and waterproofing material. While 3000 is a cross laminated HDPE carrier film, with self-adhesive for cold applications only.

But what isn’t made clear in these points?

We can’t be the only ones thinking it isn’t clear what we do with Bituthene®… So here is a list explaining WHEN, HOW and WHERE Bituthene® is actually applied to a job.

WHEN IS IT APPLIED?

All Bituthene® tapes (membranes) are applied POST concrete cure. Whether this be a culvert on a bridge or the base slab in a carpark, the base concrete MUST be cured.

RULES

- Only apply Bituthene® Tape AFTER concrete has been cured.

- Apply the correct tape for the site. If the job needs an asphalt cover, use Bituthene® 5000, if the site is a retaining wall or has a top COLD layer bituthene® 3000 may be more applicable given thickness needed.

- Asphalt should be applied to membrane as soon as possible after application.

- Apply Bituthene® tape in fair weather.

HOW IS IT APPLIED?

First the surface is prepped with a Bituthene® Primer. The Primer strengthens the adhesion between the tape and masonry surfaces. The tape itself is provided in a roll that can be cut to a specific size. This length is then rolled on to the primed surface and the backing tape is removed to expose the adhesive side of the tape. The tape is then rolled and any covered drains or utility areas are cut free of the membrane.

RULES

- Only prime the surfaces that are going to be covered by the membrane, or you will have to re-prime in 24 hours.

- ALWAYS use a primer with the tape to ensure maximum bond.

- Allow the rubber-based primer to dry for 1 hour or until tack free.

- Overlap the end pieces when starting a new roll.

WHERE IS IT APPLIED?

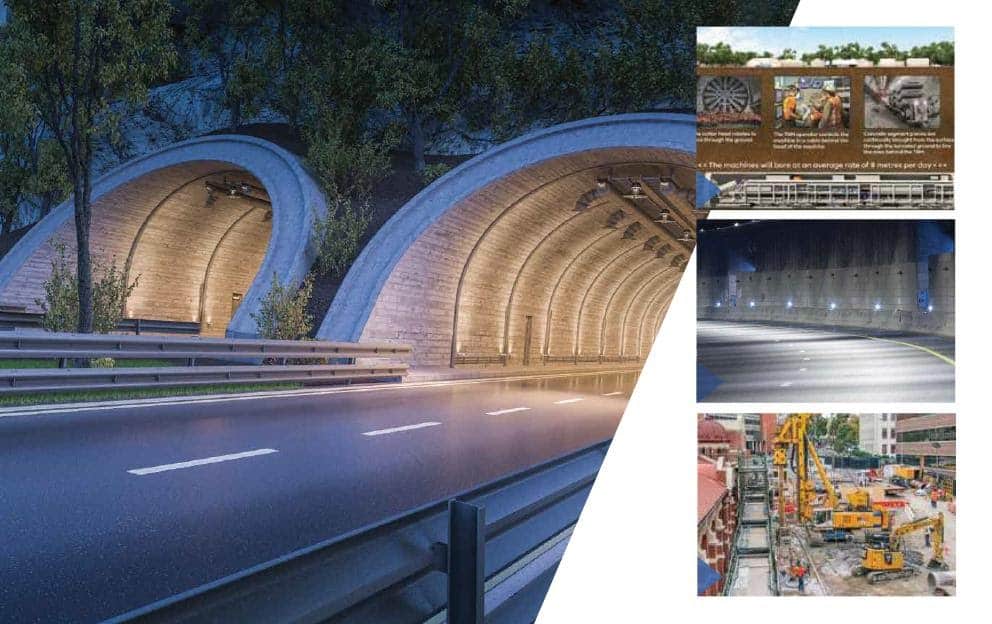

What is Bituthene® 3000 ideal for? Above grade plaza and parking decks and below grade basements, tunnels, retaining walls and other subterranean applications

We have supplied Bituthene® 3000 to Sydney Gateway, Rozelle Interchange, Westgate tunnel and more

What is Bituthene® 5000 ideal for? Bridges, walkways, roads, culverts, and other applications where asphalt is needed to cap the surface. Specially developed for use under a hot applied asphalt concrete wearing course.

We have supplied Bituthene® 5000 to Cross River Rail, Westgate tunnel, Sydney Metro and more